Leaderboard

Popular Content

Showing content with the highest reputation since 04/05/2024 in all areas

-

Elwood: It's 106 miles to Chicago, we got a full tank of gas, half a pack of cigarettes, it's dark and we're wearing sunglasses. Jake: Hit it. I've been waiting for Scalextric to release this car without the speaker on top but it hasn't happened yet so I decided to do it myself to have something different to run, don't need that extra weight up high and it wasn't on the car for most of the movie. Removing the speaker wasn't easy as the glue used to stick it on removed paint from the roof and left 4 holes all of which needed to be filled and the roof then needed a respray.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Sunday April 21st saw the Fourth Round of Carrera GT3 and we had a full field of 8 racers with a couple of new racers.Qualifying was up first with the following results: 1st Tony 8.4585 secs (new qualifying record) 2nd Hayley 8.7849,3rd Ben 8.9953, 4th Leah 8.9966, 5th Tommy 9.3111, 6th Dave 9.6519 ,7th Fred 10.0914, 8th Phil 10.2095. The race was 8 x 3 minute brackets.The results are as follows: 1st Tony 153 Laps (new record),2nd Hayley 141,3rd Leah 138,4th Ben 138, 5th Dave 139,6th Tommy 134, 7th Phil 123,8th Fred 110. Next race 5th May1 point

-

I used to buy most of my cars and parts from TopSlotsandTrains in England but they shut down a while ago now. Postage was quicker to Western Australia from England than it is from the eastern states of Australia. I use Ebay to keep an eye out for certain cars that are no longer available from retail shops but since the price of postage has gone through the roof the last few years I'm a lot more picky with what I get. Never had a problem with buying off Ebay, never had anything go missing in over 400 purchases from various countries around the world. Luckily I have a Hobby shop 5 mins away now which is now stocking quite a few brands of Slot Cars and not just Scalextric. I do like to shop around, having purchased from many Slot car outlets around the world. Matt1 point

-

From their facebook page "These are the news we have for IME Igualada. Most importantly, is the Toyota Yaris WRC2 that we will have on the market very soon, with the two decorations of Teo Martin that will be sold exclusively through his social networks in an ultra limited edition, with the rest of the decorations being normal production. It will be in plastic, 1/32 scale, 4x4 wheel drive and some other novelty... We also have some already announced and more advanced arrivals as well as a new line of parts including crowns, tires, shocks and much more.."1 point

-

1 point

-

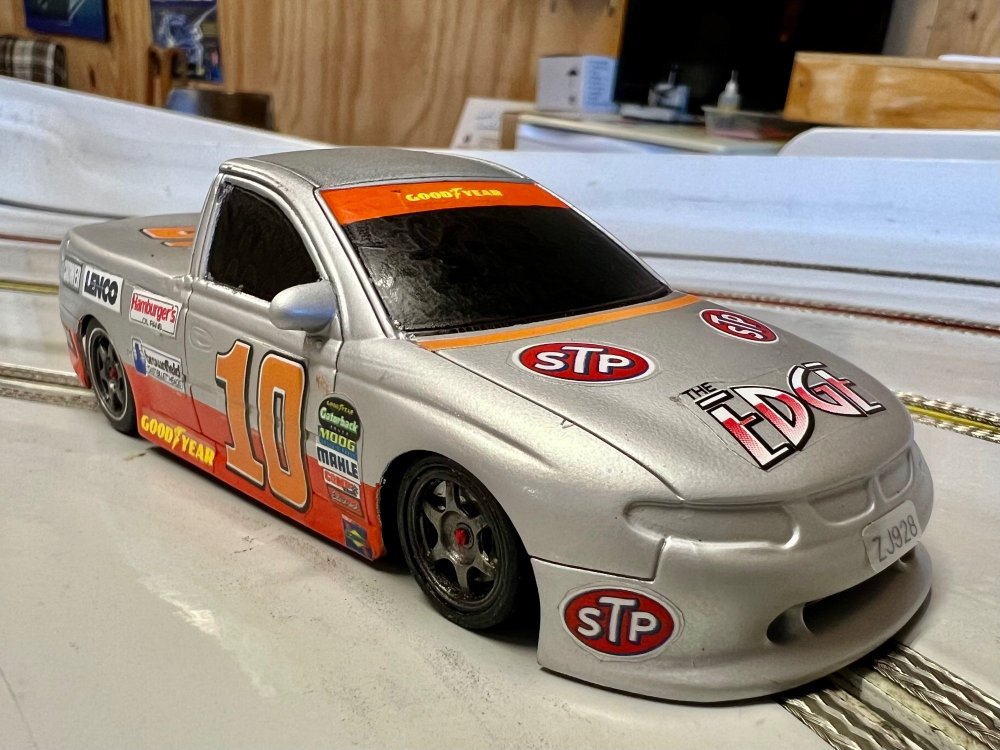

I’ve cut down a few V8 Supercars into Racing Utes before. This one runs especially well on a stock chassis that’s been lowered on cut down body posts, with Slot It running gear and alloys on the rear. Mainly NASCAR decals - thanks Pat. It’s been a hot minute since I’ve cut anything up so good to get that smell of Tamiya Putty in the air again.1 point

-

1 point

-

1 point

-

A Model King reissue of a Lindberg kit which itself was a reissue from Pyro. On model car forums this kit has a rather maligned reputation and I have to admit it really is hard work. The body is multi part consisting of sides, roof, bonnet, tail-light panel and doors. And nothing fits. After much fussing around got it together. The 'A' pillars are massive, the roof slopes down and the end of the bonnet swoops up giving the windscreen the appearance of a tank visor. The side pillars are thick and rather crude plus the rear screen is the wrong shape and too small. Still, nothing a new blade in the X-acto and the files can't fix. Finally finished but it looked wrong somehow. By happenstance I have a workshop book for the GT-6 (my parents spent the '70's working throughout South-east Asia and ended up in Madang where dad had the Triumph. They came home not long before he died in 1980, bought the book but not the Triumph). Anyways, running a ruler over the kit it looks like it's 10mm too short, I'm guessing closer to 1/27 or 1/28 scale. Certainly not the 1/25th scale it states on the box lid. In an attempt to bulk it up a bit and make it look bigger I added the wheel flares. Searching on the computer for an unrelated subject I tumbled on a photo of Brian Sampson in the AMI Racing Team Spitfire. I really liked the colour scheme so totally ripped it off, threw on some decals out of the stash and called it quits. It's safe to say my enthusiasm for the project started to wane pretty much from the get go. Thanks for looking, Chris.1 point

-

1 point